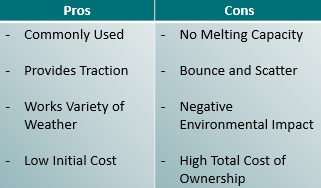

With so many anti-icing and deicing products on the market, it can be difficult to determine what product best fits your operations goals and objectives. Over the past decade, salt-based deicing products have risen in popularity and largely replaced sand due to salts increased effectiveness. However, sand is still a commonly used and helpful tool for winter maintenance. It is important to know the pros and cons of sand in order to know when it is appropriate to use.

Sand is one of the oldest winter maintenance materials. It is important to note that sand has no melting capacity which means it is not actually removing snow or ice from the road, like traditional deicers. The primary function of sand is to temporary increase traction on icy roads and surfaces. Because sand is used for traction, it is not limited to a temperature range to perform well. Sand can work to provide traction at virtually any temperature.

Additionally, the low initial cost of sand makes it very attractive to operation managers. However, the initial cost can be deceiving because later expenses add up quickly. Sand requires extensive clean-up which is additional work for maintenance crews. Sand is also not the most effective since the product is dry, it is easily blown off the road. This is known as bounce & scatter and can increase the required application rate.

If your operation uses or is considering using sand, it is important to consider prewetting the sand to reduce bounce & scatter. “Studies have shown that pre-wetting sand will enable you to reduce your sanding application rate by as much as 50%” (Cargill). Pre-wetting sand will also increase driver safety because it reduces the likelihood of debris flying up and damaging drivers’ windshields and cars.

Like all deicing materials, sand does negatively impact the environment. Sand contributes to PM10 levels. This means that tiny particles form as sand is crushed by traffic and they can remain suspended in the air which could pose a serious threat to air quality. Additionally, sand can runoff into nearby streams and waterways which negatively impacts aquatic ecosystems.

Figure #1: Pros and Cons of Sand For Winter Maintenances

So, if you are determining if sand is appropriate for your operations deicing plan you should ask yourself the following questions about your operations goals, price, and impact:

- Goal: Do I need to increase traction or increase melting capacity?

- Price: What are my operations budget restrictions? Do I want to pay less now face increased clean-up / manpower costs later or do I want to pay more now and reduce costs later?

- Impact: What is the nearby environment like? What are local and state environmental regulations?

After carefully considering what is most important to your operations goals and asking yourself these questions, you should have a better idea if sand is appropriate.

If you are still unsure, the experts at EnviroTech Services, Inc. are happy to help. Call 800-369-3878 to learn more.