EnviroTech Services, Inc.'s number one priority is to provide products that ensure the longevity of our environment in order to protect our community now and for generations to come. The process of hydraulic fracturing comes with many risks, including clay swell and fine migration.

What is Clay Swelling and Why is it a Problem?

Clay swelling is when clay expands or contracts in response to environmental factors such as wet/dry conditions, change in temperature, etc. All clay minerals have a great affinity for water but because clays differ in composition, some swell easier than others. Clay swelling is typically caused when a water-base filtrates from drilling, completion, workover, or stimulation fluids enter the formulation. Additionally, clay swelling can be caused by ion exchanges or changes in clay salinity. The nature of the reaction depends on the structure of the clay and the clay’s chemical composition at the moment of contact.

Clay swelling is a problem because it reduces the permeability of the shale due to the alteration of the clay equilibrium. Reduced shale permeability in turn reduces the amount of oil and gas frackers can extract, therefore reducing overall operation efficiency. Additionally, when freshwater causes swelling it can lead to washout, wellbore instability, high torque and drag, and stuck pipe.

How is Clay Swelling Prevented?

Clay swelling and issues associated with clay swelling are often addressed through shale inhibition. Shale inhibition refers to the chemical alternation that takes places between clay layers in a shale formation to prevent hydration and swelling. Shale inhibition helps limit clay dispersion and the accumulation of colloidal fines.

Clays are typically composed of layers of alumina silica minerals in which the outer layers have a negative charge. Cations are absorbed into the surface and the exchange of ions impacts the tendency to swell. Shale inhibition is affected by differential pressure, water activity, ion exchange, and the establishment of a fluid/shale membrane. As more water is absorbed between layers, the layers tend to break further apart.

What Are Shale Inhibitors?

Shale inhibitors work to limit the interaction clay particle has with water to mitigate issues. A common shale inhibitor that is used are polyamines. Polyamines contain active nitrogen groups that interchange with the cations on the outer layers of clays to strengthen the intermolecular forces between the clay layers to reduce the amount of water that is absorbed.

Another common shale inhibitor are glycols. Glycols provide shale inhibition through chemical adsorption and the cloud point phenomenon. At temperatures above the cloud point phenomenon, glycol solubility changes from soluble to insoluble which improves filter cake quality and protects clay pore spaces through plugging.

Brine fluids and base oil also provide inhibiting properties in drilling fluid systems. Brine fluids prevent water invasion into the formation via wellbore osmosis. Base oils used with a wetting agent ensure solids remain oil-wet which prevents clay hydration.

How Can EnviroTech Services, Inc. Help?

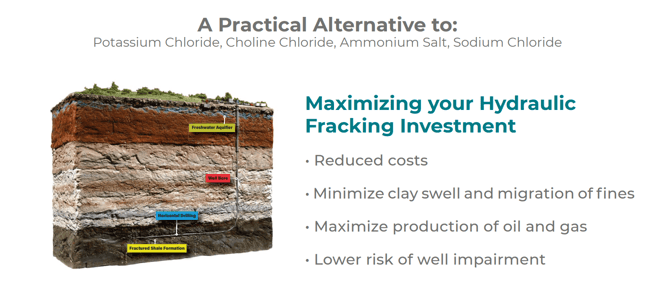

There is no argument that shale inhibition is vital, but there is often face a trade-off between well performance and cost efficiency. Thanks to PerfSaver®, EnviroTech Services, Inc.’s clay stabilization product, frackers can maximize oil and gas production and remain cost efficient.

Many water-based fracturing fluids allow clay platelets to swell and migrate in the fluid as it flows back to the wellbore. Effectively, these clay particles disperse and begin to migrate, plugging the formation matrix. PerfSaver acts to retain clay platelets in position by controlling the charge and electrolytic characteristics of the treatment. Compared to other clay stabilization products, PerfSaver shows reduced costs and improved well productivity while also ensuring the effectiveness of chemical hydraulic fluids.

Discover how EnviroTech Services, Inc. can help improve your fracking operations by visiting our website or speaking with a representative today at 800-369-3878!

Similar Reads

- How do you Control Clay Swell and Fine Migration?

- Best Dust Control Products: Landfills, Agriculture, Mining & Energy

- Dust Control Decision Making: Calcium Chloride vs. Magnesium Chloride

Works Cited

(PDF) hydraulic FRACTURING Fluid effect on Clay swelling and Water blockage in STIMULATED Naturally FRACTURED RESERVOIRS. (n.d.). Retrieved April 13, 2021, from https://www.researchgate.net/publication/322349393_Hydraulic_Fracturing_Fluid_Effect_on_Clay_Swelling_and_Water_Blockage_in_Stimulated_Naturally_Fractured_Reservoirs#:~:text=fracturing%20fluid%20into%20the%20formation%20due%20to%20viscous,which%20can%20be%20predicted%20using%20a%20geomechanical%20model.

Environmental characteristics of clays and CLAY mineral deposits. (n.d.). Retrieved April 13, 2021, from https://pubs.usgs.gov/info/clays/

Garthwaite, J. (2013, July 23). All the questions you have about fracking, answered. Retrieved April 13, 2021, from https://www.mic.com/articles/56173/all-the-questions-you-have-about-fracking-answered

Inc., N. (n.d.). Shale inhibition. Retrieved April 13, 2021, from https://www.newpark.com/drilling-shale-inhibition/#:~:text=Shale%20inhibition%20is%20affected%20by%20differential%20pressure%2C%20chemical,which%20reduces%20water%20activity%20and%20enables%20membrane%20development.

Ladd, C. C. (n.d.). Mechanisms of Swelling by Compacted Clay. Retrieved from Soil Engineering Division, Department of Civil and Sanitary Engineering, Massachusetts Institute of Technology

Oilfield Glossary. (n.d.). Retrieved April 13, 2021, from https://www.glossary.oilfield.slb.com/en/Terms/c/clay_swelling.aspx

The relationship between shale gas and other types of oil and gas reservoir (revised from Schenk C. J. & Pollastro R. M., 2001 [5]).

Tech tip 3, part ii: Shale inhibition versus encapsulation [Video file]. (2020, January 27). Retrieved April 13, 2021, from https://www.youtube.com/watch?v=Zt9aZ8bRq6s