Image credit: Bruce Gordon at EcoFlight ecoflight.org/photos/

Although fracking is commonly discussed, do you really know what fracking is?

Fracking, or hydraulic fracturing, is the process of cracking rock formations by pumping fluid into wells at a high pressure. The high-pressured liquid creates tiny cracks, known as fissures, in the rock formation, typically shale, which allows gas and oil to flow out of the rock and up to the surface. Click here to learn more about fracking issues that impact operational effectiveness.

The objective of modern fracking is to reopen the natural shale fractures and/or create new ones to maximize the volume of oil and gas extracted from the shale fractures. To maximize fracking operation efficiency, it is important ‘hold open’ the cracks in the rock formation and minimize the about of hole punctures necessary.

Shale the main rock source for oil and gas and is the most common sedimentary rock, accounting for around 70% of the rock in the Earth’s crust. It is a fine-grained rock, composed of a mix of clay minerals and mineral fragments, with low granular permeabilities. Shale is characterized by breaks along parallel layering or bedding that is less than one centimeter in thickness.

Frackers can pump up to four million gallons of fluid, as far as 10,000 feet below ground, at rates as quick as 4,200 gallons per minute. Fracking fluid is typically composed of three ingredients: water, sand, and chemicals.

A large volume of water is required to achieve the pressure needed to fracture the shale. "An Olympic-size swimming pool holds about 660,000 gallons of water, and a single fracking well can use seven or eight times that amount.” (MIC). The sand acts as a “proppant” and keeps cracks in the shale open. This allows gas and oil to be released from the rock and up the well. Frackers can also use ceramic pellets or other similar particles to achieve this. Chemicals are added to help dissolve minerals, reduce friction, prevent corrosion, thicken the fluid to transport sand, clean out debris, fight bacteria, and prevent clay swelling.

However, combine fracking fluids with PerfSaver® from EnviroTech Services, Inc. helps maintain the integrity of fracture networks when water-swelling clays are present to ensure the effectiveness of hydraulic fluid treatments.

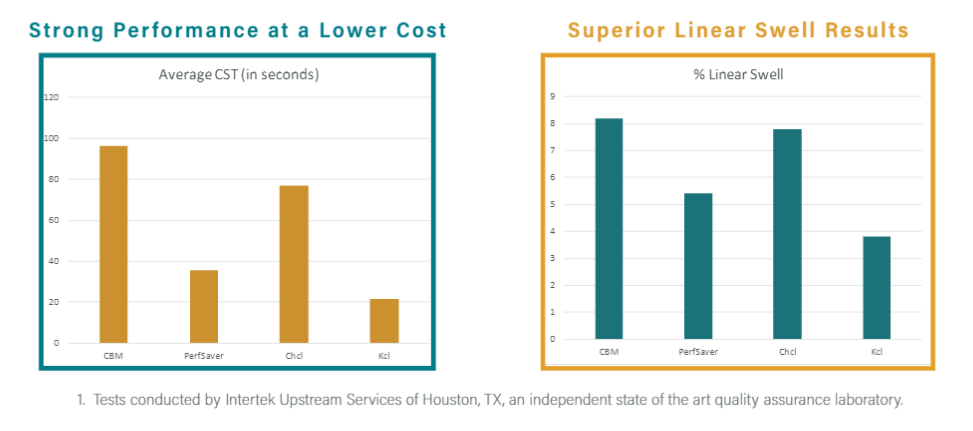

The Capillary Suction Time (CST) Test was developed at the Water Pollution Research Laboratory in Stevenage, England and is a widely used method for characterizing fluid filterability and the condition of colloidal materials in various applications. PerfSaver's results from the CST test demonstrates strong performance compared to popular alternatives. A Linear Swell Meter Test was also conducted on PerfSaver and competing products. This test examines the tendency for a shale to absorb liquid from water-based fluids. This leads to swelling of the shales and often causes lower productions and swollen cuttings. A laboratory using the linear swell meter can determine the amount of fluid absorbed by shale over time.

The Capillary Suction Time (CST) Test and the Linear Swell Meter Test were conducted by a third party; Intertek Group based in Houston, Texas, to ensure accurate and unbiased results.

The tests conducted on PerfSaver show the product's benefits and high-performance ability compared to alternatives. PerfSaver maximizes your hydraulic fracking investment by reducing costs, minimizing clay swell and migration, maximizing production of oil and gas, and lower risk of well impairment.

Learn more about how EnviroTech Services can serve you by visiting our website or request a FREE site evaluation.

Similar Reads

- How do you Control Clay Swell and Fine Migration?

- Best Dust Control Products: Landfills, Agriculture, Mining & Energy

- Dust Control Decision Making: Calcium Chloride vs. Magnesium Chloride

Works Cited

(PDF) hydraulic FRACTURING Fluid effect on Clay swelling and Water blockage in STIMULATED Naturally FRACTURED RESERVOIRS. (n.d.). Retrieved April 13, 2021, from https://www.researchgate.net/publication/322349393_Hydraulic_Fracturing_Fluid_Effect_on_Clay_Swelling_and_Water_Blockage_in_Stimulated_Naturally_Fractured_Reservoirs#:~:text=fracturing%20fluid%20into%20the%20formation%20due%20to%20viscous,which%20can%20be%20predicted%20using%20a%20geomechanical%20model.

Environmental characteristics of clays and CLAY mineral deposits. (n.d.). Retrieved April 13, 2021, from https://pubs.usgs.gov/info/clays/

Garthwaite, J. (2013, July 23). All the questions you have about fracking, answered. Retrieved April 13, 2021, from https://www.mic.com/articles/56173/all-the-questions-you-have-about-fracking-answered

Inc., N. (n.d.). Shale inhibition. Retrieved April 13, 2021, from https://www.newpark.com/drilling-shale-inhibition/#:~:text=Shale%20inhibition%20is%20affected%20by%20differential%20pressure%2C%20chemical,which%20reduces%20water%20activity%20and%20enables%20membrane%20development.

Ladd, C. C. (n.d.). Mechanisms of Swelling by Compacted Clay. Retrieved from Soil Engineering Division, Department of Civil and Sanitary Engineering, Massachusetts Institute of Technology

Oilfield Glossary. (n.d.). Retrieved April 13, 2021, from https://www.glossary.oilfield.slb.com/en/Terms/c/clay_swelling.aspx

Tech tip 3, part ii: Shale inhibition versus encapsulation [Video file]. (2020, January 27). Retrieved April 13, 2021, from https://www.youtube.com/watch?v=Zt9aZ8bRq6s